Checking Out the Midst: A Comprehensive Overview to Concrete Scanning and Its Diverse Applications

In the world of construction and facilities development, the precise procedure of concrete scanning holds an essential duty in making sure the structural honesty and safety and security of jobs. As modern technology remains to develop, the applications of concrete scanning have actually increased much past mere surface-level evaluations. From detecting rebar and post-tension cable televisions to drawing up gaps and conduits concealed within concrete frameworks, the abilities of modern-day scanning methods are both crucial and remarkable. Nonetheless, truth deepness of concrete scanning's prospective reaches also better, branching right into unexpected fields and triggering ingenious services. The interconnected internet of possibilities that concrete scanning presents is not only remarkable but additionally vital for the improvement of various industries.

Relevance of Concrete Scanning

Recognizing the importance of concrete scanning is important in ensuring the safety and security and integrity of structures throughout building and construction and restoration projects. Concrete scanning uses sophisticated modern technologies such as ground-penetrating radar (GPR) and electro-magnetic induction to detect ingrained things, voids, or various other anomalies within concrete structures - RainierGPR Concrete Scanning. By carrying out detailed scans before boring, cutting, or coring into concrete, construction groups can prevent unintended damage to vital structural components like rebar, conduits, or post-tension cable televisions. This aggressive method not only prevents costly repair work and job delays yet also boosts overall construction security by reducing the danger of structural failings or collapses as a result of compromised stability.

Additionally, concrete scanning plays a pivotal duty in ensuring compliance with structure codes and policies that mandate the security of existing structural parts during construction activities. By precisely mapping out the interior make-up of concrete, scanning technologies enable building experts to make enlightened choices that support the structural stability and toughness of buildings and facilities projects. Basically, the value of concrete scanning exists in its ability to protect both the structural stability and the workers included in building and construction undertakings.

Technologies Utilized in Concrete Scanning

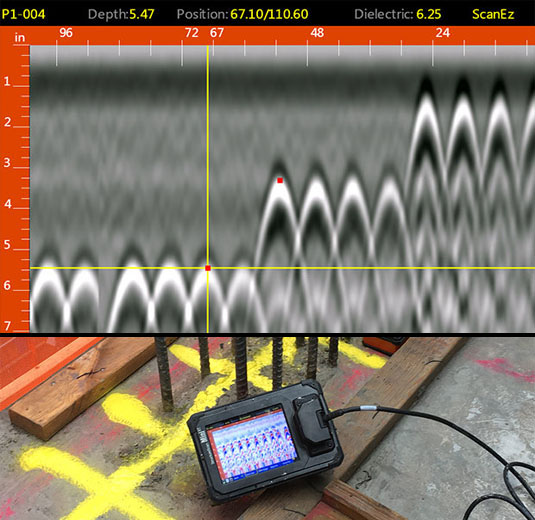

Concrete scanning counts on innovative innovations such as ground-penetrating radar (GPR) and electromagnetic induction to precisely identify ingrained items and anomalies within concrete frameworks. Ground-penetrating radar runs by producing high-frequency electro-magnetic waves right into the concrete. When these waves encounter different products or gaps within the concrete, they recuperate to the surface, enabling the GPR system to produce a comprehensive subsurface photo. This innovation is particularly efficient in situating rebar, post-tension cable televisions, conduits, and various other items embedded in concrete.

Electromagnetic induction, on the other hand, works by producing magnetic fields around a concrete structure through a transmitter coil. When metal objects are present within the concrete, they interfere with these electro-magnetic fields, causing eddy currents to flow via the metal. By determining the adjustments in the electromagnetic areas with a receiver coil, the system can identify the place of metal objects in the concrete.

These innovative innovations play a critical duty in non-destructive testing, making sure the security and stability of concrete structures in various industries.

Applications in Building Sector

Within the construction market, concrete scanning innovation discovers internet diverse applications that enhance task performance and safety and security. Additionally, concrete scanning is utilized for finding voids, such as air pockets or locations of degeneration within concrete, which can endanger the total strength of a framework. Concrete scanning plays an essential role in quality control by confirming the density of concrete covers over support, making certain conformity with style requirements and requirements.

Safety Advantages of Concrete Scanning

In the realm of building and construction safety, the application of concrete scanning innovation presents a vital benefit in preemptively determining possible dangers and fortifying structural stability. By making use of advanced scanning approaches such as ground-penetrating radar (GPR) and electro-magnetic induction, building and construction teams can properly locate rebar, post-tension cable televisions, avenues, and various other hidden things within concrete frameworks. This proactive method significantly lowers the risk of accidental strikes during boring, cutting, or coring tasks, thus stopping pricey problems, injuries, and task hold-ups.

Furthermore, concrete scanning improves worker safety by giving real-time info about the structural condition of concrete aspects. By dealing with possible security issues quickly, concrete scanning adds to creating a secure working atmosphere and mitigating the likelihood of architectural failures or accidents on building and construction sites.

Future Fads in Concrete Scanning

Emerging improvements in scanning innovation are positioned to transform the area of concrete evaluation and analysis. One significant pattern that is obtaining traction is the combination of fabricated intelligence (AI) and equipment knowing formulas into concrete scanning devices. By harnessing the power of AI, these systems can examine vast amounts of information gathered throughout scanning processes to supply even more accurate and thorough insights into the condition of concrete structures. This Recommended Reading can help in finding surprise defects, forecasting potential structural failures, and even suggesting maintenance methods.

Another substantial fad is the growth of even more mobile and straightforward scanning devices. Miniaturization of scanning equipment allows for simpler access to constrained rooms and remote areas, making assessments a lot more thorough and reliable. Furthermore, improvements in cordless communication technologies make it possible for real-time information transfer and analysis, facilitating quicker decision-making processes.

Furthermore, there is a growing concentrate on sustainability in concrete scanning innovations - RainierGPR Concrete Scanning. Producers are significantly integrating green materials and energy-efficient features right into their gadgets to minimize environmental influence. These future patterns are readied to enhance the effectiveness, precision, and sustainability of concrete scanning methods, forming the market's future landscape

Conclusion

Finally, concrete scanning plays an important duty in the construction industry by making certain the safety and security and effectiveness of numerous tasks. By utilizing advanced modern technologies, such as GPR and radar imaging, experts have the ability to accurately detect potential dangers within concrete frameworks. The applications of concrete scanning are large and proceed to develop, making it a vital device for maintaining the stability of structures and infrastructure. As modern technology developments, the future of concrete scanning holds encouraging developments for enhancing construction procedures.